TTS offers a wide array of common mills and bits, including specialized designs like Twister Mills and Carbide Insert Mills. In highly deviated wells, the use of an XRV™ (Extended Reach Vibratory Tool) allows access to greater depths by reducing friction lock caused by helical buckling. These, along with a rugged motor designed to handle harsh conditions in horizontal wells, simplify the process of milling plugs, valves, concrete, etc.

Milling & Cleanout Services

MOTOR RUNS PER MONTH

AVG. PLUGS MILLED PER DAY

COUNTRIES

WORKED

TOOLS

SPECIALISTS

ACTIVE MOTORS IN RENTAL FLEET

OF TOTAL JOB VOLUME ARE MOTOR JOBS

TTS’ rugged milling BHA is designed to withstand the demanding side loading stresses associated with working in horizontal wells. From top to bottom, this tool string was engineered to reach TD.

- Versatile BHA Components

- Proprietary Equipment

- Rugged Design

- External Slip Coiled Tubing Connector

- Back Pressure Float Valve

- HydraSet™

- Hydraulic Disconnect

- Circulating Sub

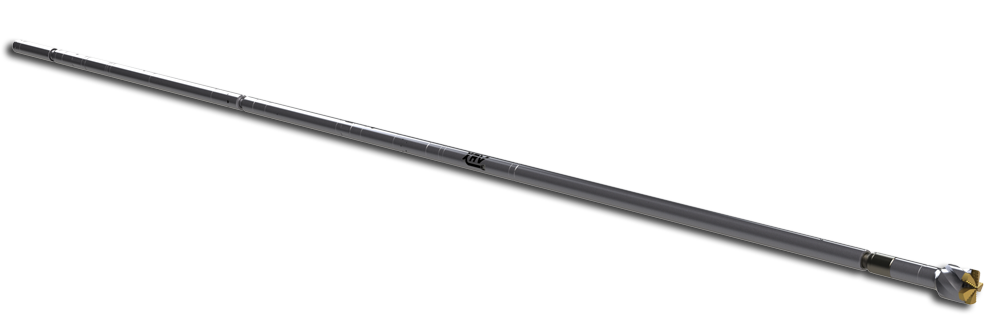

- XRV G3

- Titan Downhole Motor

- Carbide Mills

The standard for normal cleanouts, the carbide mill can have any combination of shapes and sizes to meet customer needs.

Designed without any moving parts or elastomers, this vibratory tool enables coiled tubing to reach depths that were previously unobtainable.

Used for releasing the coiled tubing from the BHA if it becomes stuck in the wellbore.

Used to free immobilized tool strings in the wellbore. The HydraSet™ Jar has a hydraulic assist feature for resetting the tool for subsequent impacts.

Provides a means of connecting a BHA to the end of coiled tubing.

Provides a means of connecting a BHA to the end of coiled tubing.

Provides a mean of circulation to the annulus upon activation.

This rugged downhole motor provides many hours of reliable service under demanding operating conditions.